Browse Items(53 total)

- Subject is exactly "Salz Tannery"

Sort by:

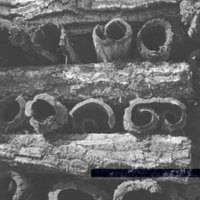

Tanoak bark was stacked for drying. Originally harvested locally, tanoak provided the chief ingredient in tanning California Saddle Leather (TM), a Salz specialty. As local supplies dwindled, Salz purchased it from suppliers throughout California.…

Date: 1954

Type: PHOTO

Bark storage was crucial to the smooth operation of Salz Tannery. You needed to cut and store enough bark to last for a year. There was no protection from fire at the River Street sheds.

Date: 1954

Type: PHOTO

The forklift was the modern day replacement for the dray horse. Even into the late 1950's, bark was stored and dried across River Street from the main Salz Tannery complex and transported across River Street/Highway 9 as needed.

Date: 1954

Type: PHOTO

Joe Bellas, plant superintendent at the Salz Tannery during the 1950's holds the finished leather product. Bellas was Yugoslavian, and according to the Lezin family "tough and fair".

Date: 1954

Type: PHOTO

Salz employee Red McCafferty and a co-worker work with a machine called a "splitter" to separate the hide structure into two distinct layers. Splitting the leather into a thinner, more pliable form, increased its markets.

Date: 1954

Type: PHOTO

A Salz employee illustrates the scudding process that removed fine hair roots from the hides. It was a very exacting and challenging task. The implement used was a large, dull blade. The hide was stretched over a wooden, sloped structure designed…

Date: 1954

Type: PHOTO

Ansel Adams photographed this Salz employee to illustrate a typical beamhouse outfit. The coverings were made of leather for safety because the "beamhouse" was where hides were tanned in large open pits.

Date: 1954

Type: PHOTO

Mel Stubendorff and an unnamed Salz Tannery co-worker tack the hides up to large boards prior to drying. The drying process usually took several days.

Date: 1954

Type: PHOTO

The spray machines at Salz Tannery needed to be constantly adjusted. Depending on the finish required, the spray booths deposited waxes, lacquers, oils, dyes, pigments and protein solutions on the leather. Before this, the leather was dried. After…

Date: 1954

Type: PHOTO

Glazing Salz's California Saddle Leather TM involved using a glazing jack. Each side of the hide was glazed twice to create a mirror-like surface. The protein (albumin) used in the glazing process was derived from egg whites. After drying on the…

Date: 1954

Type: PHOTO