Browse Items(53 total)

- Subject is exactly "Salz Tannery"

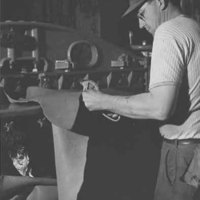

Date: 1954

Type: PHOTO

Date: 1954

Type: PHOTO

Date: 1954

Type: PHOTO

Date: 1954

Type: PHOTO

Date: 1954

Type: PHOTO

Date: 1955

Type: PHOTO

Date: 1954

Type: PHOTO

Date: 1954

Type: PHOTO

Date: 8/4/2001

Source: Santa Cruz Sentinel, August 4, 2001. Staff writer Stett Holbrook contributed to this article.

Type: ARTICLE

Date: 8/4/2001

Source: Santa Cruz Sentinel, August 4, 2001. Sources include Sentinel archives and historian Carolyn Swift.

Type: ARTICLE